Blog & Company News

MODAPTS® 2023 Training Conference

Ed Eisbrenner, founder of Eisbrenner Productivity Group, traveled to sunny Florida to instruct and enjoy the International MODAPTS® Association’s MODAPTS® 2023 Training Conference. The Practitioner Training Class was well-attended, as was the rest of the conference....

Ed to Attend the International MODAPTS® Association Conference

Ed Eisbrenner enjoys being an IMA Certified instructor, especially when his work takes him to sunny Florida! This April, Ed is excited to attend the Spring 2023 IMA Training Conference as an IMA Certified Instructor. He is passionate about teaching people so that they...

Eisbrenner Productivity Group Certifies Employees of Rivian

Ed Eisbrenner returned to Rivian this past week to help more employees obtain their MODAPTS® Certifications. Rivian is an innovative car manufacturer that believes in making better vehicles for the planet. Ed is eager to help more people earn their MODAPTS®...

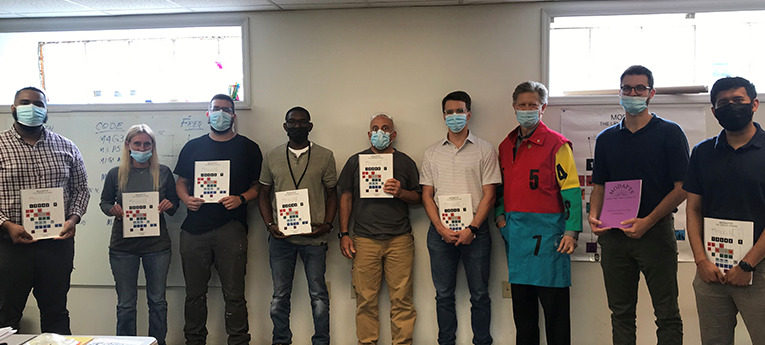

MODAPTS® Training and Certification Class with BLOX, Bessemser, AL

Ed Eisbrenner, the founder of Eisbrenner Productivity Group, had an excellent time training with employees of BLOX in Bessemser, AL on May 5, 2021. They learned more about how to apply MODAPTS® to their everyday work practices.MODAPTS® is a tool for analyzing human...

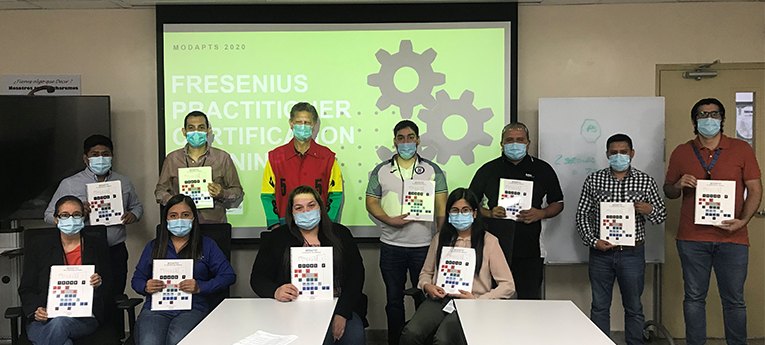

MODAPTS® Class at FMC in Reynosa, MX

Ed Eisbrenner of Eisbrenner Productivity Group traveled to FMC in Reynosa, MX on September 17, 2020 for a MODAPTS® Training and Certification class. EPG provides On-Site MODAPTS® Training and Certification to companies who would like employees to become MODAPTS®...