What are Bottlenecks and Why Do They Matter?

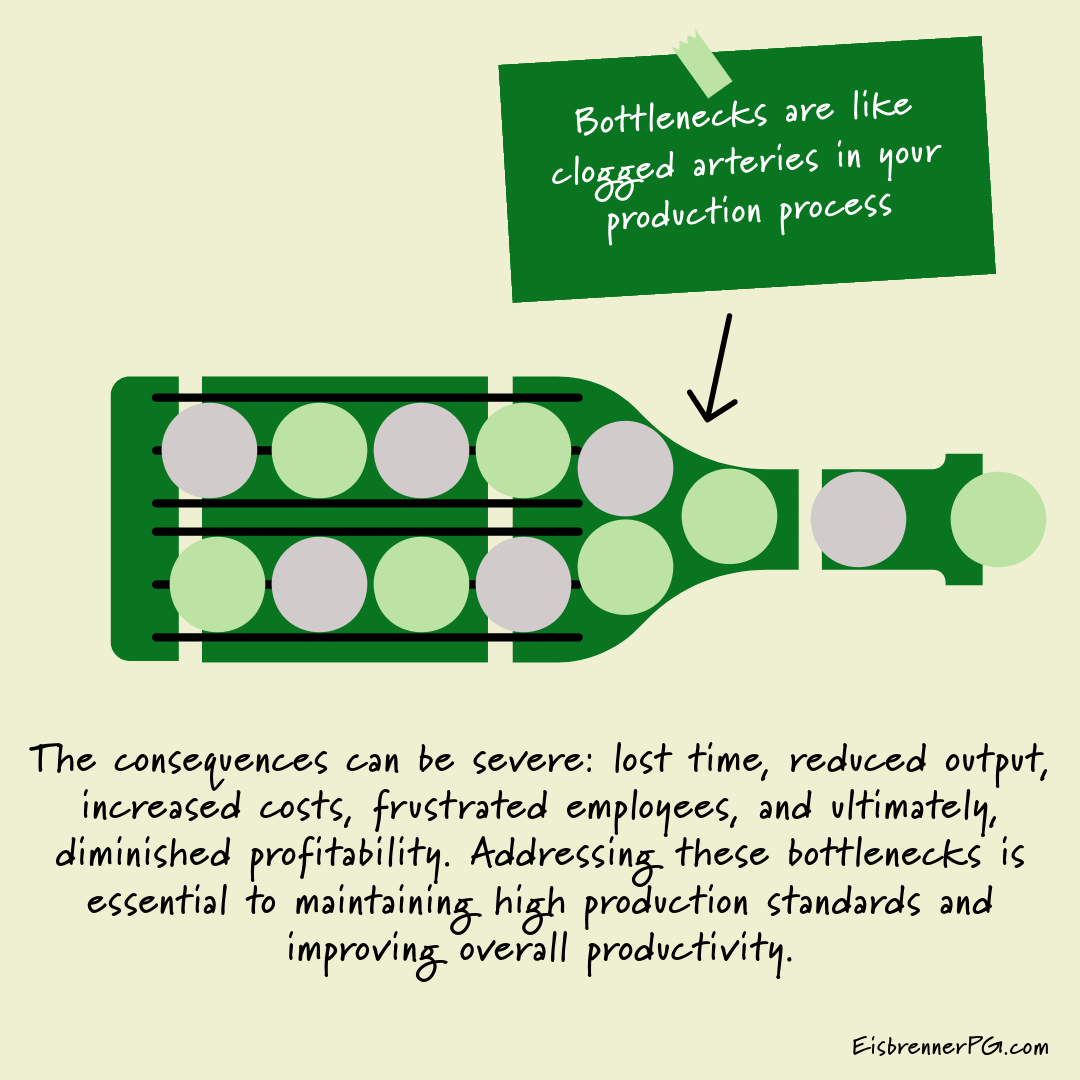

Bottlenecks are like clogged arteries in your production process. There are specific areas or steps in your workflow where work accumulates, delays occur, and output is drastically reduced. These hold-ups can manifest in various forms: maybe it’s a particular machine that can’t keep up with the pace, a manual task that takes too long, a disorganized workstation, or inconsistent workflow processes. The consequences can be severe: lost time, reduced output, increased costs, frustrated employees, and ultimately, diminished profitability. Addressing these bottlenecks is essential to maintaining high production standards and improving overall productivity.

Introducing MODAPTS®: Your Key to Identifying and Resolving Bottlenecks

So, how do you pinpoint these problematic areas and use data to resolve them? This is where MODAPTS® (Modular Arrangement of Predetermined Time Standards) can help. MODAPTS® is a work measurement system that allows for a detailed analysis of any task by breaking it down into its fundamental movements and assigning a time value to each. Unlike traditional time studies that rely on stopwatch timings, MODAPTS® uses predetermined time values based on the body part moved. This system enables us see where time is spent on a particular task. It also allows us to identify non valved added or wasteful motions.

Identifying Bottlenecks with MODAPTS®: A Microscopic Look at Your Processes

With MODAPTS®, we can look beyond the big picture and examine the minute details of each step in your production workflow. When we analyze these activities through the MODAPTS® lens, we can determine precisely how long each element takes. By identifying VA, NVA, or NVABN to each process step, we can easily focus on potential improvemnet steps. By quantifying and visualizing these time measurements, MODAPTS® provides the data to reasonably identify those critical areas where time and efficiency are lost.

Analyzing Root Causes: It’s Not Just About Time

It’s critical to remember that MODAPTS® data isn’t just about counting seconds in a process; it is about efficiency. The system reveals the underlying delay causes by pinpointing non-valued added motions, such as unnecessary reaches, bending, or walking time. If a process includes repetitive motions that can be streamlined, this will stand out very clearly with a MODAPTS® analysis. With this level of detail, we can make informed decisions to improve the overall process and productivity.

Implementing Improvements and Supercharging Productivity

Once the bottlenecks have been identified and the root causes analyzed, MODAPTS® provides the roadmap for improvements. This could mean eliminating unnecessary steps, reorganizing workspaces to minimize worker movement, identify ergonomic concerns or providing targeted training to address inefficiencies. By applying these solutions, you’re not just tweaking a process; you’re transforming it – making it more efficient, more reliable, and more profitable. By implementing MODAPTS® principles into your continuous improvement program, your team will begin to see an increase in productivity and create reliable production standards.

See it in Action: How MODAPTS® Unclogs a Bottleneck

To truly appreciate the power of MODAPTS®, imagine a skilled operator struggling with a complex task. The process has multiple steps, some of which are not required. The operator struggle to perform each step, wasting valuable time. Now, imagine the same task performed after MODAPTS® analysis has identified and rectified the NVA (Non Value Added), movements. The operator can perform the task smoothly identifing and eliminating unnecessary steps. This real-world example is what MODAPTS® aims to do for your business.

The Path to Higher Production Standards

Using a MODAPTS® analysis to identify bottlenecks quickly, your business has a clear path toward improving operator utilization and efficiency using solid data. If you’re ready to unlock your business’s potential by eliminating bottlenecks, improving your productivity, and raising your production standards, contact us today to discuss how MODAPTS® can transform your operation.

Whether you want to certify your team members or have Ed Eisbrenner conduct an analysis of your existing production standards, the Eisbrenner Productivity Group is here. Schedule a free consultation to learn more about how EPG can help your business thrive.

In today’s competitive landscape, maximizing productivity through continuous improvement is paramount for businesses across all industries. Every second counts and inefficiencies in your production process can significantly impact your bottom line. One common culprit that silently sabotages output is the presence of bottlenecks. These are points in your workflow where tasks slow down, creating delays and hindering the overall flow. Identifying and resolving these bottlenecks is crucial for improving production standards and achieving optimal utilization of your operator’s time while assembling products. But how can businesses effectively pinpoint these problem areas and implement lasting solutions? The answer lies in a powerful work measurement tool: MODAPTS®. “The Language of Work.”